In simple terms, the process of making masterbatch is divided into two process stages, collect the required materials and then mixing all the material together with added heater to produce homogeneous pellets. Generally, high or low speed mixer is used to produce pre-mixed additives were then mashed in a roller mill, kneaders and single or twin extruders secrew. Distribution (dispersion) is flat and homogeneity of the additives is very important. This processing depends on several key elements are formulations, quality of raw materials, the quality of mixing and compounding. The end of the pellet-shaped masterbatch manufacturing process (silindrical or spherical).

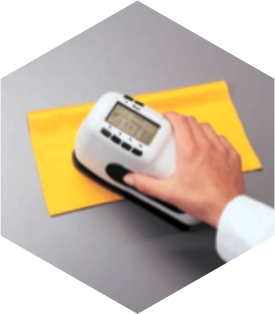

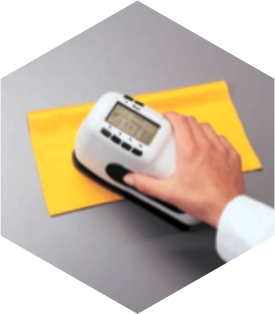

Masterbatch can be described as an additional polymer in plastic production process in a variety of applications. Mixing masterbatch most appropriate in volumetric dosing method or gravimetric dosing. Volumetric dosing method is a method of mixing the resin and additives (masterbatch) with a bulk density approach, while the gravimetric dosing method is a method of mixing the resin and additives (masterbatch) with the approach of the unit of mass. Volumetric dosing has the advantage that capital investment is relatively lower but requires calibration every times to change the masterbatch (depending on the bulk density of the material). While the resulting mixture gravimetric dosing is very accurate, but the cost is relative expensive.

Injection molding, blow molding, profile extrusion, plastic sheets, film extrusion, cast film, fiber and a calendered sheet and plastic production process using masterbatch.

The benefit of using masterbatch is to produce a mixture homogenenity better color than the pigment. If you want to mix colors, additives, and polymer (Commodity polymer, engineering polymer, etc.) into a masterbatch, we can provide the solution.